LaFourche Sugars

Systems and components

-

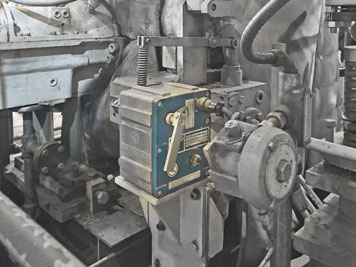

1 x HEINZMANN Si-TEC Xtend CGC-T governor

-

1 x HEINZMANN StG30 Actuator

-

1 x HEINZMANN Sapphire II Overspeed Protection Device

-

1 x HEINZMANN Si-TEC Xtend GSM control

Upgrade of steam turbine and power management control

LaFourche Sugars LLC located in Thibodaux, Louisiana, USA is one of the leading sugar mills operating in Louisiana, producing 120,000 tonnes of raw sugar annually. Apart from sugar production, the mill also had a Co-Generation plant comprising of 1 x 4.5 MW steam turbine generator, with 650 PSI supply steam. Apart from producing power to reduce the mills’ import power from the Grid supply, the steam turbine generator also produces exhaust steam pressure at 180 PSI, for supply steam to the steam turbine drives (e.g., mills, fans, pumps, etc.) as well as the entire factory electrical load. The main issue that LaFourche Sugars faced was poor regulation of steam turbine control (via the existing WW 505 digital governor and EG10P electro-hydraulic actuator) requiring manual intervention by the operator during synchronizing, loading, and load variation during abnormal boiler conditions.

HEINZMANN Australia was able to engineer the optimum solution through the CGC-T integrated governor system controlling the StG30 actuator, resulting in a smooth and seamless automatic control system solution for the customer, while integrating the system upgrade in the existing control panels (after the removal of WW 505 governor).

The CGC-T system provided automatic start-up sequence, optimum steam turbine governing control, automatic synchronizing control, kW and PF control, as well as “Process Control” via inlet steam pressure control @ 650 PSI. This control mode helped guarantee a fully automatic control system with seamless control during normal and abnormal conditions, preventing the steam turbine from tripping, and helping with smooth recovery after the abnormal boiler steam pressure was overcome. In addition, the CGC-T maintained smooth turbine control in Island mode (frequency control) during the sudden loss of Grid supply, safeguarding the factory operations until re-synchronizing back with the Grid supply. The overall customer feedback was positive, with smooth control and simplified operations.

Application Type: Co-Generation Power Plant (Sugar Mill)

Turbine Type: 1x Elliott United Technologies backpressure steam turbine generator

Power Output: 1x 4.5 MW

Country: USA